ANSUL Proportioning Foam Trailers Models - PFT

The ANSUL® proportioning foam trailers (PFT) are designed to provide mobile fire protection for flammable liquid hazards typically found in such areas as refineries and associated tank farms, chemical processing plants, truck and rail car unloading facilities, and marine terminals.

Please Select Tank Capacity:

| Source Availablity | |||

|---|---|---|---|

| Hub Location | Quantity | Delivery Time | |

| Select an option to update the sources list | |||

|

Selected

|

days | ||

| This product is currently out of stock in all of our hub locations. | |||

| Availability |

Out of stock |

|

|---|---|---|

| SKU | PFT | |

| Price Unit | Each | |

| Usually ships in | 2-3 Days |

* The ultimate shipping cost will be displayed during the checkout process

Quick Quote

Description

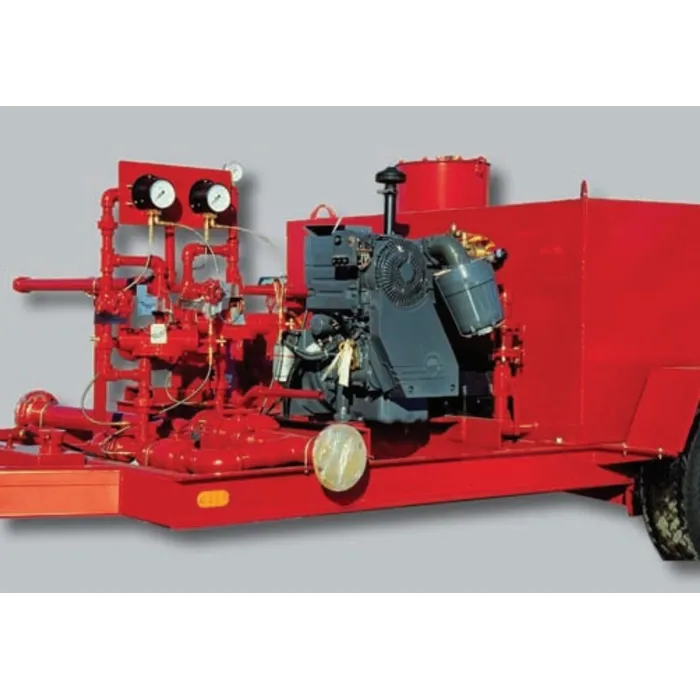

ANSUL Proportioning Foam Trailers Models - PFT

The ANSUL® proportioning foam trailers (PFT) are designed to provide mobile fire protection for flammable liquid hazards typically found in such areas as refineries and associated tank farms, chemical processing plants, truck and rail car unloading facilities, and marine terminals. These trailers provide foam solution to delivery devices such as foam handline nozzles and portable monitors; or in semi-fixed applications supplying stationary monitors, sprinkler systems, foam makers and chambers, or storage tank sub-surface foam injection devices. The ANSUL PFT series substantially increase the fire fighting capabilities of industrial, municipal, and military fire departments without the costs associated with a truck chassis. The ANSUL proportioning foam trailer (PFT) consists of the following:

- A trailer assembly constructed of structural steel channel with axle(s), wheels, and tires designed to carry the gross weight of the trailer with associated equipment and foam concentrate.

- Choice of concentrate tanks in 500, 750, or 1000 U.S. gallon (1893, 2839, or 3785 Liter) capacities constructed of carbon steel in accordance with NFPA 11C ‘‘Mobile Foam Apparatus’’ with required swash partitions and removable gasketed top for ease of inspection and cleaning.

- Reliable in-line balanced pressure proportioning system with dual proportioners in parallel to enable wide proportioning flow range with minimum friction loss – less than 10 psi (69 kPa).

- Positive displacement foam concentrate pump driven by air cooled diesel engine complete with electric key start and instrumentation. Pump constructed of materials compatible with all types of foam concentrates and capable of being engineered for use with 1%, 3%, or 6% foam concentrates. Manually-operated clutch to engage or disengage engine while in stand-by condition. The in-line balanced pressure proportioning system functions by maintaining an equal pressure in the foam concentrate and water inlets to the proportioner. This balancing ability allows the proportioner to be used over a wide range of flows and pressures. The system will also respond quickly and accurately to changes in the water inlet pressures and flow rates.

- A pressure control valve, located in the return line to the foam concentrate storage tank, is set to maintain a regulated pressure in the supply manifold that is higher than the pressure in the water supply line. The foam concentrate that is not required by the proportioner is returned to the atmospheric storage tank through the pressure control valve. The spool valve senses the foam concentrate pressure and automatically balances it with the water pressure.

- A duplex pressure gauge provides a reading of the foam concentrate and water pressure. The foam concentrate then enters the proportioner where a built-in orifice regulates the flow of pressurized foam concentrate entering the water stream. The trailer is supplied with flanged inlet and outlet for connection to customer-supplied fitting or manifold. Upon request, ANSUL can supply inlet and outlet manifolds constructed to customer specifications.

FEATURES

- High capacity flow

- Extremely mobile

- Rugged construction

- Wide proportioning range

- Designed per NFPA 11C

- Diesel driven balanced pressure proportioning system

- Easy refill during operation

- Multiple tank options

- UL Listed and FM Approved proportioning system

- Torflex axle assemblies

- Tanks constructed by ASME qualified welders

- Highway ready

SPECIFICATION

- Finish – The complete proportioner foam trailer assembly shall be properly prepared and painted with a red enamel paint system.

- Trailer Frame – The trailer frame shall be constructed of structural steel meeting the requirements of ASTM A-36. The trailer shall be equipped with 3 in. lunette eye hitch, adjustable tongue dolly with wheel and full light package for highway use.

- Axles – The axle(s) shall be rated a minimum of 7000 lb. load rating. The axle(s) shall consist of progressive torque action and independent wheel movement to provide maximum shock absorption and handling characteristics.

- Brakes – The brakes shall be 12 x 2 in. electric type brakes approved by CSA (Canadian Standards Association).

- Tank – The tank shall be constructed in accordance with the requirements of NFPA 11C, ‘‘Mobile Foam Apparatus.’’ It shall be fabricated by welders qualified per Section IX of the ASME Code. The tank shall be mounted to the trailer frame utilizing cushioning system consisting of spring mounting pads to minimize tank flexing.

- Proportioning System – The in-line balanced pressure proportioner assembly shall contain all necessary components including foam proportioner; pressure balancing spool valve; duplex gauge; control, drain and check valves; interconnecting brass pipe and valve identification nameplates. Balancing shall be accomplished through the use of a spool-type pressure balancing valve. This valve shall sense foam concentrate and water inlet pressures at the outer ends of a dumbbell-shaped piston and shall react to pressure changes by covering or uncovering the foam supply port to the proportioner. The balancing valve shall be of C83600 brass construction with a phosphor-bronze piston and Buna-N rubber O-rings and Seals. Interconnecting foam concentrate piping shall be of brass construction. The in-line balanced pressure proportioner shall be completely pressure tested by the manufacturer.

- Approval – The in-line balanced pressure proportioner assembly shall be listed by Underwriters Laboratories (UL) and approved by Factory Mutual (FM).

- Manufacturer – The manufacturer of the proportioning foam trailer shall have a minimum of 10 years experience in the manufacture and design of fire suppression systems and related fire equipment. The foam trailer and the foam concentrate shall be the products of the same manufacturer.

More Information

| SKU | PFT |

|---|---|

| Usually ships in | 2-3 Days |

| Manufacturer | ANSUL |

| Brand | ANSUL |

| Price Unit | Each |

| Country of Manufacture | United States |

| Is Featured | No |