What are the OSHA Emergency Safety Shower Requirements?

OSHA 29 CFR 1910.151(c) focuses on emergency showers and eye wash stations specifically by addressing the need for facilities to enable workers to flush themselves of corrosive materials.

It states, "Where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use."

Other emergency safety shower standards address specific industries and the hazards associated with them. For example: facilities with open tanks must have an emergency safety shower (or an alternative) within easy reach -- this typically covers dipping and coating applications. Also, the pulp and paper industry must provide facilities to counteract lime or acid burns.

While they cover a lot, the OSHA emergency shower and eye wash station requirements don’t hit every mark. They do not specify details about safety shower functionality or location.

What are the Main Safety Shower Requirements?

- Install as per ANSI Z358.1 Requirements.

- The Location of Emergency Shower and Eyewash Stations.

- The Flow Rates for Emergency Shower and Eyewash Stations.

- The Operation for Emergency Shower and Eyewash Stations.

- The Water Temperature for Emergency Shower and Eyewash Stations.

ANSI Requirements: Location of Emergency Shower and Eyewash Stations

The first few seconds after a person is exposed to hazardous chemicals are critical. The longer the substance remains on the skin, the more damage occurs. To meet the ANSI Z358 requirements, the emergency shower and eyewash station must be within 10 seconds reach from where an accident occurs. That’s approximately 55 feet. The emergency safety equipment should also be installed on the same level as a potential hazard.

Keep the path to the emergency shower and eyewash station unobstructed, In case vision is affected. Locate the safety shower and eye wash equipment in a clearly visible, well-lit position.

ANSI Requirements: Flow Rates for Emergency Shower and Eyewash Stations

Emergency showers must flow at a minimum rate of 20 US gallons (76 liters) of potable water per minute, for 15 minutes. This ensures enough time to remove contaminated clothing and rinse any chemical residue.

Likewise, emergency eyewashes must deliver at least 3 US gallons (11.4 liters) per minute, for 15 minutes. This ensures a thorough decontamination.

ANSI Requirements: Operation for Emergency Shower and Eyewash Stations

Even with impaired vision, emergency shower and eyewash stations must be easy to access and operate. The control valves must switch from ‘off’ to ‘on’ in one second or less. These valves should be designed so the flushing flow remains on without the use of the operator’s hands.

ANSI Requirements: Water Temperature for Emergency Shower and Eyewash Stations

ANSI Z358 requires emergency shower and eyewash stations to provide tepid water in the range of 60 F to 100 F (16 C to 38 C). Temperatures that exceed this range can scald the injured person and cause a higher rate of chemical absorption by the skin. Lower temperatures can lead to hypothermia or thermal shock. The affected person is less likely to remove their contaminated clothing in cold water, thus prolonging exposure to the chemical substance.

Meeting the ANSI Z358 temperature requirements is important to ensuring a worker’s safety. If the water temperature is uncomfortable, it’s natural human behavior to step out of the safety shower before the full 15 minutes is up. This reduces the rinsing effectiveness and increases the chance of injury due to hazardous chemical burns.

- What are the ANSI recommendations?

The ANSI/ISEA Z358.1 standard provides guidelines for the location and performance of emergency eye wash and shower station. It states the equipment must be on the same level and within 10 seconds of an identified chemical hazard – approximately 55 feet. The path to reach it must be free of any obstacles or equipment.

- What are nearby risks and hazards?

Perform a risk assessment. Identify hazards such as chemicals, lubricants, and airborne substances where the SDS Section 4 requires specific equipment for skin and eyes. Discuss potential problems with your team. A common-sense approach will ensure that immediate and easy access is available for victims of chemical splashes to decontaminate. A hazard with a higher risk for injury may require safety equipment to be closer to it than the ANSI standard specifies. But, be sure not to locate it so close to a hazard that it becomes contaminated when in operation.

- Are the emergency showers and eye washes highly visible?

Keep the area around the hazard and leading to safety showers well lit. Emergency shower and eyewash stations must be clearly marked with signage that is visible from any direction that a worker may approach the equipment.

- Are there enough safety shower stations throughout the workplace?

A lab or indoor work area is often congested with many workers performing different tasks. A single incident in the room could affect other personnel not directly involved. Keep in mind the potential number of workers affected by an incident when planning how many emergency eye wash and showers are necessary in an indoor area.

How often should a safety shower be inspected?

According to ANSI/ISEA Z358.1-2004, plumbed emergency eyewash and eye/face wash stations should be visually inspected and activated every week. Equipment requires annual servicing to ensure effective operation. Proper training covering the location and use of the eyewash is also vital during an emergency.

- Is the path to the emergency eyewash station well-lit and obstacle-free?

Personnel sometimes leave equipment or tools nearby or in the direct path of an eyewash station, not realizing it could impede someone’s access in an emergency. If a chemical splash has already impaired a person’s vision, obstructions in the path of the eye wash could cause further injuries.

- Is the eye/face wash clearly visible and demarcated?

Over time, labels and signs weather and may even fall off. Update and replace signs as necessary. Make sure there is enough light in the station’s area.

- How is the flow and pressure of the water when activated?

Scale buildup in the nozzles or piping impedes the water supply. Test weekly to minimize this risk and identify potential problems such as low flow rates. ANSI requires emergency eye washes to deliver a flow of at least 1.5 liters/minute (.4 gallons/minute), for 15 minutes. Eye/face wash stations must flow at 11.4 liters/minute (3 gallons/minute). Correct any water supply issues immediately.

- Is there dirt or rust in the water?

Tiny particles found in sediment, dirt or rust can cause further damage to the eye. Check water supply filters and flush the emergency eye wash equipment until all contaminants are out of the system.

- Are there any electrical connections close to the eye wash or eye/face wash station?

Water and electricity don’t mix. Electrical outlets should be six feet away unless protected by Ground Fault Circuit Interrupters. Keep all electrical equipment at least three feet away from an emergency eye wash station.

- Does the supply valve remain open after activation?

ANSI specifies emergency eyewash stations should only switch off when the operator intentionally closes the valve. If the activation valve closes and stops the flow without this intervention, repair the system as soon as possible.

- Are all employees properly trained in how to use emergency eye wash and eye/face wash equipment? Do they all know where it is located?

Any personnel that could be exposed to hazardous materials should be trained in how to use the eyewash equipment. Keep in mind, depending on the industry, some employees wear many hats. It can be difficult to keep everything straight, including how to operate emergency eyewash stations. Employees that work in multiple departments might even forget the location of the equipment in certain areas of the facility. Thus, regular, ongoing training on all safety equipment is critical. In addition to employee orientation training, offer regular training refreshers for existing employees. Have employees act out how to use the equipment during an eye injury situation. If unable to do so, evaluate and update current training procedures

- Is the nozzle protection working as designed?

To prevent squirting dirt or dust into someone’s eyes on activation, ANSI requires all nozzles to be protected from airborne contaminants. Ensure the nozzle caps come off with water flow as designed. Request or perform maintenance if there is any malfunction of the nozzle protection.

Emergency Showers Specifications and Types:

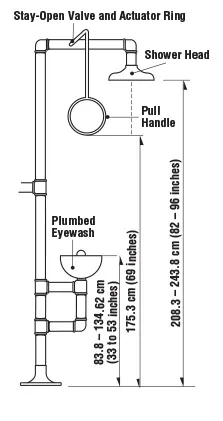

The emergency shower should deliver a pattern of water with a diameter of at least 50.8 cm (20 inches) at 152.4 cm (60 inches). This diameter ensures that the water will come into contact with the entire body - not just the top of the person's head. ANSI also recommends the shower head be between 208.3 and 243.8 cm (82-96 inches) from the floor. The minimum volume of spray should be 75.7 litres/minute (20 gallons/minute) for a minimum time of 15 minutes.

The shower should also be designed so that it can be activated in less than 1 second, and it remains operational without the operator's hand on the valve (or lever, handle, etc.). This valve should not be more than 173.3 cm (69 inches) in height. If enclosures are used, ensure that there is an unobstructed area of 86.4 cm (34 inches) in diameter.

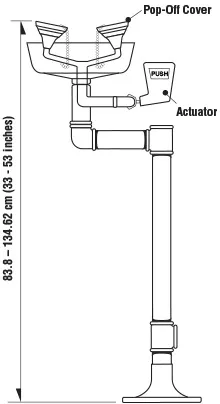

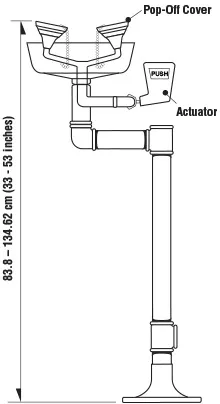

Eyewash stations should be designed to deliver fluid to both eyes simultaneously at a volume of not less than 1.5 litres/minute (0.4 gallons/minute) for 15 minutes. The combination eye and face wash stations require 11.4 litres per minute (3.0 gallons per minute). However, in either case, the volume should not be at a velocity which may injure the eyes. The unit should be between 83.8 and 134.6 cm (33 to 53 inches) from the floor, and a minimum of 15.3 cm (6 inches) from the wall or nearest obstruction.

With an eye wash station, the user should be able to open their eyelids with their hands and still have their eyes in the liquid. In the case of the eye/face wash, the user should have enough room to allow the eyelids to be held open with the hands while the eyes and face are still in the stream. As with the shower, the unit should also be designed so that it can be activated in less than 1 second, and it remains operational without the operator's hand on the valve (or lever, handle, etc.) with the valve being located in an easily located place. Since the nozzles to eyewash stations typically need to be protected from airborne contaminants, the units are to be designed such that the removal of these covers should not require a separate motion by the user when the unit is activated.

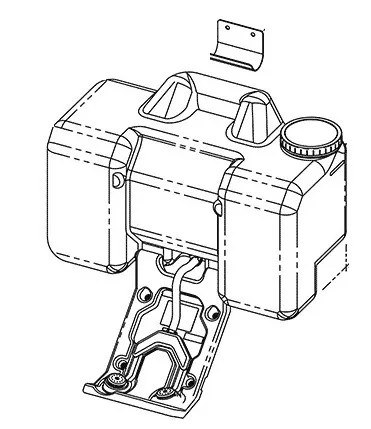

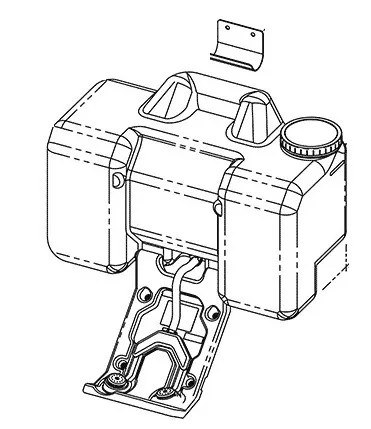

Install and maintain according to the manufacturer's instructions. Similar requirements apply as with the plumbed units regarding the unit's ability to provide flushing liquid for at least 15 minutes, accessible access, and to deliver tepid flushing fluid.

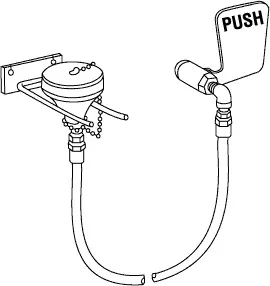

Drench Hoses

Drench hoses may be used to "spot" rinse an area when a full shower is not required, to assist a person when the person is unable to stand or is unconscious, or to wash under a piece of clothing before the clothing is removed. The ANSI standard states that a drench hose may be considered an eyewash or eye/face wash if the drench hose meets the performance requirements as listed in the standard.

Further Reading:

References: