How to store and care your PPE, Arc Flash Suit and Firefighter GEAR

In 2014, NFPA 1851 was established to set requirements for the proper selection, care, and maintenance of firefighting protective gear to reduce health and safety risks associated with improper maintenance, contamination, or damage. Sections 6.1 through 10.1.1 detail procedures for inspecting, cleaning, repair, storage and eventual retirement of PPE. While these regulations are clear and to the point, sometimes firehouse culture and traditions can get in the way of common sense safety.

The days of being a “smoke eater” fighting a fire without SCBA are long gone and for good reason; breathing in smoke is inherently bad for you. The same is true of wearing soiled PPE. It’s not a badge of honor or courage—it’s a serious health risk. Multiple studies have found that soiled PPE can be impregnated with an extremely dangerous cocktail of hazardous chemicals and known carcinogens. Studies by the American Society of Testing Materials (ASTM) have also determined that accumulated soot on PPE can:

- Diminish its ability to reflect radiant heat.

- Make it increasingly ignitable.

- Reduce its ability to repel water.

- Increase its electrical conductivity.

- Weaken the fabric making it susceptible tears and punctures.

Proper cleaning, maintenance, and storage of protective clothing are essential to improving firefighter health and safety. The following requirements are per NFPA 1851, Standard on Selection, Care and Maintenance of Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting, 2014 Edition. It should be noted that this standard is a comprehensive user document, and all fire personnel should read it to get a fuller picture of PPE cleaning, maintenance, and storage.

The proper way to perform advanced cleaning (machine washing)

- Front loading washing machines (aka extractors) are preferable.

- Do not overload the machine.

- Pre-treat heavily soiled or spotted areas. Do not use chlorine bleach, chlorinated solvents, active-ingredient cleaning agents, or solvents without element manufacturer’s approval.

- Separate outer shells from liners, remove drag rescue devices and suspenders, and wash independently.

- Turn the liner system inside out.

- All closures (zippers, hook and D-rings, plush and loop) must be fastened prior to laundering.

- Water temperature should not exceed 105 degrees F.

- Use mild detergent (pH factor of 6.0 to 10.5), as indicated on safety data sheet or product container.

- Adjust the washing machine so that the g-force does not exceed 100 g (follow machine manufacturer instructions for proper setting or program selection).

- Inspect after cleaning and rewash if necessary.

- If the machine is also used to launder items other than protective ensemble elements, the machine must be rinsed out by running the machine without a laundry load through a complete cycle with detergent and filled to the maximum level with water at a temperature of 120°F to 125°F.

- Dry in an area with good ventilation; do NOT dry in direct sunlight.

- Ensure that all closures are fastened prior to drying.

- If machine drying, do not overload capacity of machine; use “no heat” or “air dry only” option.

- If machine drying, basket temperature should not exceed 105°F.

The proper way to store gear

- Store in a clean, dry, well-ventilated area.

- Elements must be clean and dry before storage.

- Store away from direct sunlight or any UV-producing lights.

- Do not store in temperatures above 82° degrees F or below -32°F.

- Do not store in vehicle trunks, unless protected by a gear bag or other covering.

- Do not store in airtight containers, unless new and unused.

- Do not store in contact with oils, solvent, acids, alkalis, or other contaminants.

- Do not store in personal lockers or living quarters.

- Proximity elements shall be stored by hanging to limit damage caused by creasing or folding.

The proper way to maintain gear

- Gear should be routinely inspected after each use, by the wearer, looking for any signs of damage. If any type of damage, discoloration, or degradation is present, the garment should be forwarded to the safety officer or other authority having jurisdiction for further assessment.

- NFPA 1851 requires any field repairs to be performed by the original manufacturer, a verified independent service provider (ISP), or a member of the department who has had the required level of training.

- All repairs shall be done in like manner as manufacturer using NFPA-compliant materials.

- Basic repairs shall be limited to the following: patching of minor tears, char marks, and ember burns; repairing of skipped, broken, and missing stitches; replacement of missing hardware, excluding hardware that is part of positive closure system; reclosing of the liner of a garment after complete liner inspection.

- When performing repairs, remove the liner system from the outer shell to avoid accidental damage.

- Repairs must be made to all layers of the garment that have been damaged. If there is a tear or burn in the outer shell, check the thermal liner and moisture barrier to make sure these layers were not affected.

- Patches shall be limited to a maximum 160 cm2 (25 in2). The finished edges of patch shall extend at least 1 inch in all directions beyond the damaged area, with no raw edges on the patch to prevent fraying. A patch should be large enough to allow for turning under all edges at least a half- inch on each side.

- Where installing a patch to the outer shell, it is recommended that the interior of the fabric be patched as well to prevent further damage from washing and general wear.

- If replacing trim or covering trim with an option, any covered trim must be replaced unless otherwise indicated by the manufacturer [of the trim]. Trim patches must not exceed 3 inches in length and must extend 1 inch beyond the damaged area, with a maximum of 2 patches per trim stripe allowed.

- No repair shall result in a reduction of the minimum required visibility pattern specified in the standard.

- Re-stitching more than 1 inch of an outer shell Major A seam, or a thermal liner Major B seam, requires consulting the manufacturer.

- Repairs to moisture barrier seams require consulting the manufacturer.

- Patches to the moisture barrier must extend at least ½” in all directions beyond the edge of the damage. If the barrier has damage measuring more than ½” or a tear larger than 3” in length, a patch consisting of the same moisture barrier fabric shall be used for repair, unless otherwise indicated by the manufacturer.

- Replacement of entire component layers shall only be undertaken by the manufacturer.

- Manufacturer should always be consulted if unsure of the complexity of the repair.

Avoid OSHA Citations: How to Properly Store PPE?

Respirator Storage Tips

Respirators have especially stringent OSHA storage requirements. In November 2020, OSHA listed improper respirator storage as a common COVID-19 citation. Standard 1910.134(h)(2)(i) requires respirators to be stored in a way that protects them from damage and contamination and prevents facepieces and respirator valves from being deformed.

Manufacturer 3M recommends these storage practices for N95 respirators:

- Store respirators in their original packaging.

- Store respirators in clean air.

- Store respirators out of direct sunlight.

- Store respirators in a rigid space where they won't be crushed or become misshapen.

- Store respirators in a climate-controlled place where the humidity and temperature don't exceed the manufacturer's recommended limits. These can differ depending on the model. For example, instructions for one model specify that it be stored in an environment that's not above 86° F, not below -20° F and not above 80% relative humidity.

Hard Hat Storage Tips

OSHA recommends that protective headgear be stored out of direct sunlight, which can damage them. Loss of surface gloss, chalking and flaking on the shell or brim of a hard hat are signs that it may have been exposed to excessive heat or sunlight and should be replaced.

Fall Protection Harness Storage Tips

According to Safety+Health magazine, fall protection harnesses should be stored hanging, flat or neatly folded to prevent unnecessary wear. They should be kept dry and away from temperature extremes. Dirty harnesses should be cleaned immediately and dried before storage, following the manufacturer's instructions. Typically, manufacturers recommend that harnesses be dried and stored away from direct sunlight and heat. If the webbing feels excessively brittle or hard, this can be a sign of damage from heat or sunlight, according to a manufacturer's inspection guide.

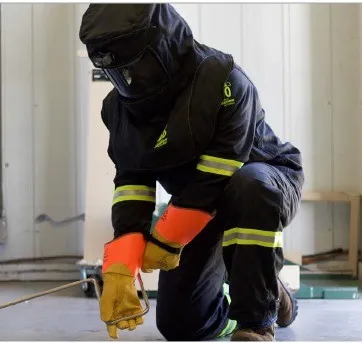

How to clean and storage Your Arc Flash Suits.

INSTRUCTIONS ON STORAGE

- Use a storage bag or storage locker in a clean dry environment. Never store with sharp objects, or in dusty areas.

- To avoid color fading and loss of strength never store under direct sunlight or other UV light sources (UV radiation does not affect heat and flame protection)

- Front flap of the hood should be used to protect the window inside of the storage bag; otherwise hood

- storage bags are avail

- When placing the hood inside of a storage bag flip up the front flap to cover the hood shield window.

- Recommend folding the arc flash suit coat, bib-overall or coverall before placing in storage.

- Be sure all powered components are turned off before storage including the fan unit and LED l

- To ensure the hood ventilation system fan does not turn on while using a storage bag, disconnect the fan unit from the coupling (turn fan counter clockwise), open battery storage compartment cover and remove one battery. Replace the battery compartment cover and store in a pouch inside of the overall storage bag.

WASHING PROCEDURES

The following instructions apply to domestic as well as Industrial washing. Load of washing machine 2/3 of volume of the drum in order to avoid crumples. Prewashing at temperatures up to 40°C with a washing bath relation of 1 :10. Main washing at temperatures up to 40°C with a washing bath relation of 1:10.

DETERGENTS

To wash PPE in a correct way, the bath should have a ph-value <1 0. General commercial detergents for colored clothing can be used and proportioned according to the detergent manufacturers' information. Full detergents contain brighteners and are therefore not suitable. Do not use bleaching agents or products which contain bleaching agents.

FABRIC SOFTENER

Do not use fabric softener.

RINSING

After washing, PPE shall be rinsed carefully in order to remove all remains of alkaline and/or possibly flammable residues of the detergent. Up to 2-3 rinsing cycles may be necessary.

DRYING

Garments may be spin-dried and dried in a cylinder drying machine with low or normal temperatures until a remaining.

IRONING

Do not iron.

DRY (CHEMICAL) CLEANING

Chemical drying is recommended when clothing becomes very dirty by e.g. oil or grease. Dry cleaning shall be done according to the care labeling by usual 2-bathprocedure. Boosters should only be used in extreme situations and only with reduced mechanism. Dry cleaning shall only be executed by experts. Before PPE is re-used it shall be completely free of solvents. Therefore the clothing should ventilate for at least one day after being cleaned.

General PPE Storage Best Practices

OSHA may not have specific guidance on storing other types of PPE, but that doesn't mean you should store it carelessly. The "Handbook of Occupational Safety and Health," edited by S. Z. Mansdorf, recommends the following general practices for PPE storage:

- Keep the storage area clean and dry.

- Keep the PPE away from direct sunlight when stored.

- Train users on how to store PPE correctly.

- Consult the manufacturer's instructions for more specific guidance.

PPE made from highly engineered materials may have more stringent storage requirements. For example, Bulwark recommends storing its fire-resistant clothing in lockers, drawers or closets, while DuPont recommends storing its encapsulated garments in boxes, in bags or on hangers and warns against compression (stepping on or placing heavy object on the garments).

When deciding where to locate your PPE storage, it's also a good idea to choose a place that's as convenient as possible for workers. The more conveniently located your PPE storage, the more likely that workers will use the equipment when they need it. When the storage area is not convenient, some workers may keep their protective equipment in toolboxes, on worktables or in other places where it might get dirty or damaged. And other workers may forgo PPE altogether.

It's also smart to stay organized. Storing PPE using wire shelves, storage cabinets and bins can make it easier and faster for workers to find the right equipment in the right size.

PPE is a critical line of defense against the dangerous environment in which you perform your duties. Keeping your gear clean, well maintained, and properly stored, contributes to your health and safety.